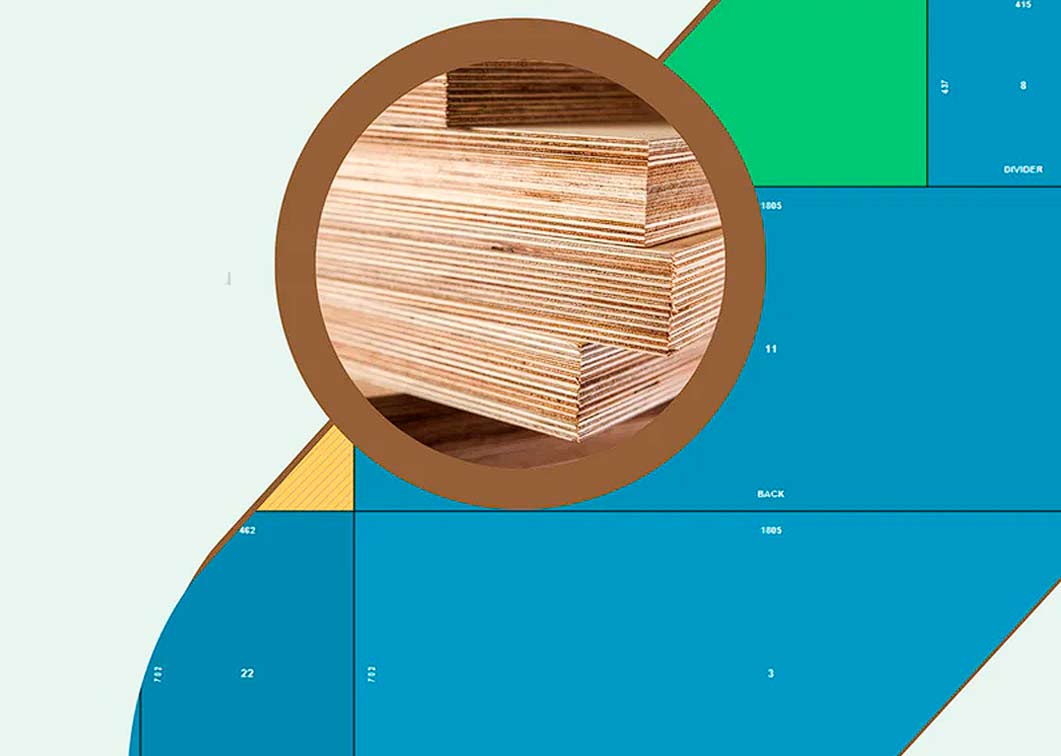

For woodworkers as well as DIY enthusiasts, the selection of materials can make or break a project. Solid wood is a timeless material, but engineered wood products such as MDF (Medium Density Fiberboard) as well as melamine and particle boards are an excellent alternative. Understanding their unique characteristics is essential to create stunning and practical designs.

MDF Board: Smoothness, Multi-purpose and the Champion!

MDF boards are used as a standard in woodworking shops all over the world. Their smooth consistent surface is perfect to work on, easily accepting paint, stain, and veneers. As opposed to solid wood, MDF boards boast consistent density throughout, which eliminates concerns regarding cracks or warping. The consistent nature of MDF boards allows them to be used for complex carvings, moldings, and for creating intricate architectural elements.

MDF Boards are a great option to cut costs.

Smooth surface: This permits for the application of paint or veneer that is smooth providing a professional look.

The ability to work: MDF board is easy to cut, drill and cut and. This makes it ideal for intricate designs.

MDF Boards are strong and Long-lasting: MDF boards of high quality can withstand daily water and wear regardless of their appearance.

Flexibility: From making furniture to constructing cabinets or even building architectural components, MDF boards have a diverse range of applications.

Melamine Sheets The durability of the sheets blends with style

Melamine sheets provide a stylish accent to MDF boards. They have a fine layer MDF made of melamine resin which is later bonded to create a visually pleasing and durable surface. Melamine is available in an array of patterns and colors.

Melamine sheets are a great choice for many reasons.

Resistant to stain and scratch: The melamine surface provides an extraordinary level of protection to stains and scratches. They are ideal in areas that experience many people, such as bathrooms and kitchens.

Easy Maintenance: Melamine sheets require minimal upkeep. They are maintained simply by wiping them down using a damp sponge.

Cost-effective Alternative: Melamine sheets that are akin to solid hardwood but possess more aesthetic value and are a cost-effective alternative with a high-end appearance.

The versatility of Melamine Sheets is what makes them an great for both commercial and residential projects.

Budget-Friendly Particle Board

Particle board, while a less popular choice compared to MDF and melamine, offers the most cost-effective option for projects where structural integrity has precedence over aesthetics. It is made of compressed wood particles, and then bonded with resin, it provides some degree of robustness and stability.

Understanding Particle Board:

Cost-effective: Particle board is the least expensive choice of the three.

Application Limitations: Particle board’s rougher, more porous surface and low water resistance make it ideal for situations where aesthetics is not the primary issue. Examples include internal furniture pieces and subflooring.

Particle Board is susceptible to moisture. It may expand, and its structural integrity could be compromised when exposed to water. It is essential to select the most resistant to moisture when working in humid conditions.

The Right Engineered Wood Panel

Selecting the right engineered panel for your project will depend on the specific requirements and goals. This is a brief breakdown to help you make a decision:

MDF boards have a smooth finish, intricate designs and versatility.

If durability, scratch resistance and a pre-finished finish are essential: Melamine sheets offer the perfect combination.

For projects with a tight budget and in which structural integrity is the main concern the use of particleboard is an option.

The Future of Woodworking: Embracing Engineered Wood Options

MDF, melamine, and particle boards offer an endless array of options for woodworkers and DIY enthusiasts. They’re a wonderful option for any toolkit because they are affordable, versatile and reliability. As technology advances it is possible for more innovative engineered wood solutions to appear, expanding the creative possibilities for the future of woodworking.