The incorporation of robotic arms into manufacturing automation has emerged as an enormous force changing the face of manufacturing and production processes. Thanks to the advancement of technology robotic arms, sometimes referred to as Arm robot industrial have emerged as essential instruments, delivering unprecedented precision, efficiency and security across a variety of industries. This article explores the many capabilities of robotic arms and their effect on business operations in Australia.

Robotic arms, also known as robot arms, are a variety of mechanical devices that mimic the functionality of human arms, albeit with enhanced precision and endurance. They are utilized extensively in various industries, including manufacturing electronics and automotive. Pharmaceutical companies also utilize for their precision. Robotic arms can be programmed, making it possible to seamlessly integrate them into different production environments. They are able to provide a dynamic capability and flexibility to change operating requirements.

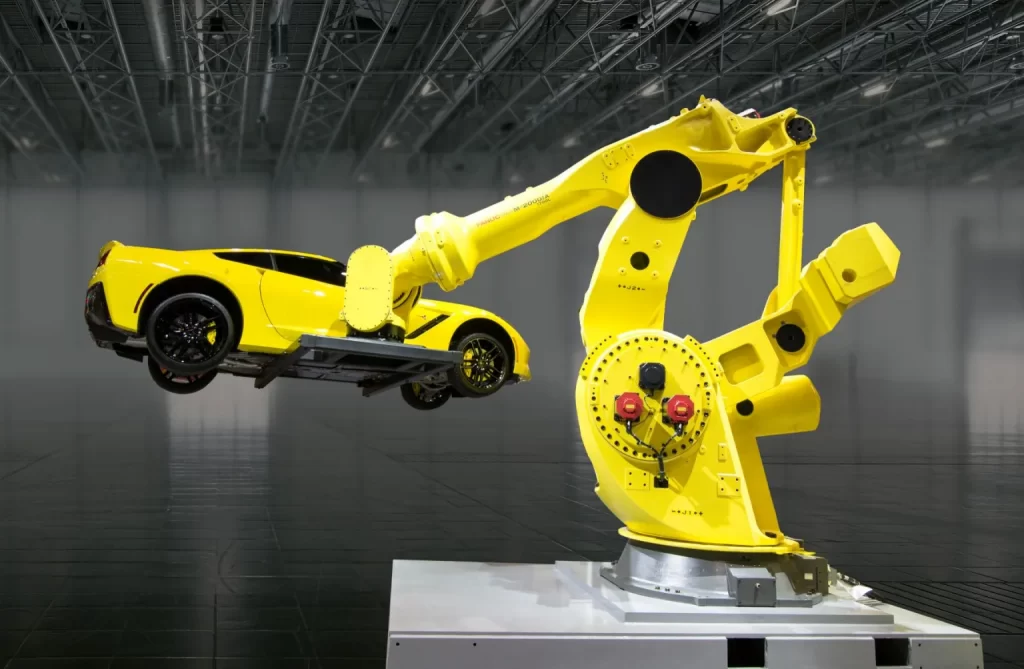

The robotic arm, a cornerstone in the modern world of automation, has a sophisticated kinematic system of joints that can rotate and execute linear displacements. This allows robotic arms to move through complicated spatial configurations, and manipulate objects with a meticulous concentration on detail as well as ensuring the highest level of safety for human operators. Because of this, companies have taken robotic arms as essential assets which have streamlined production processes and increasing efficiency at unprecedented levels.

One of the defining features of robot arms is the utilization of end effectors that serve as the functional equivalent of human hands. End effectors, which are typically tailored to specific tasks, have a major role to play in determining the range of robotic arms’ applications. Robot hands that have specialized end effects can perform many different tasks, ranging from lifting heavy objects and gripping them to delicately attaching complex components. For more information, click Robotic Arm

The introduction of robotic arms into industrial automation has brought about an exciting new era of productivity and innovation. With the help of robotic arms, companies can optimize their manufacturing processes, decrease human error, and enhance overall quality of the product. The seamless coordination between robotic arms as well as automated systems have led to significant advancements in operational efficiency, enabling businesses to meet the demands of customers with incredible speed and precision.

The transformational impact of robotic arms extends beyond the mere automation of processes; it is a fundamental change in the definition of industrial processes. Industrial robotic arms have not only revolutionized manufacturing processes, but also opened the door to new production methods. Due to their capability of performing tasks in hazardous or challenging environments robotic arms have increased worker safety and opened up new opportunities to perform complex manufacturing operations.

The evolution of robotic arms technology has also resulted in the development of end effectors specifically designed to meet the needs of specific industries. These modern end effects, that have the latest sensory and gripping technologies, have broadened the scope of applications that robotic arms can perform.

Australia is taking on the potential for automation of robotic arms. Businesses have the opportunity to improve their competitiveness and operational capabilities. The incorporation of robotic arms into industrial workflows have the potential to boost productivity and drive growth. Robotic arms, which are designed with precision and efficiency in mind, can open new frontiers for industrial automation. Companies can reach unprecedented levels of operational excellence.

In conclusion, integration of industrial and robotic arms is a major advancement in the field of industrial automation. Robotic arms, thanks to their unparalleled precision, flexibility and safety capabilities have redefined modern manufacturing. They provide businesses with a competitive advantage in a marketplace that is becoming more competitive. Businesses will reap the benefits as Australia is embracing robotic arms technology. This means increased productivity, operational efficiency and technological innovation.